Super board is

a kind of high performance insulation board covered with non- flammable CRC & gypsum board.

Owing to the continuous production facilities, Sake could provide the super board to the interior and exterior process on construction field.

We are taking the human ecology and habitat culture into deep consideration.

As a result, we do not use artificial adhesive to make a natural conditions in housing.

Because we are making the super board as a thermal laminating and conveyor belt-molding type, it is not necessary to use the chemical bondage.

Since it is VOC ZERO product, there are no harmful atmosphere in the house.

Because of Automatic Conveyor Machine, continuous mass production is possible and as a result we could mitigate cost of construction materials.

Product’s Benefits

1. Fire combustibility – resistant to heating loss and fire

CRC board, GYPSUM, artificial stones and marbles are used in the making process of PIR laminating, SUPER BOARD is an excellent fire retardant materials.

Non flammable and in organic matters could avoid the possibility of fire ignitions.

Because it is made of mineral materials, we can expect stable and safe standard in housing area.

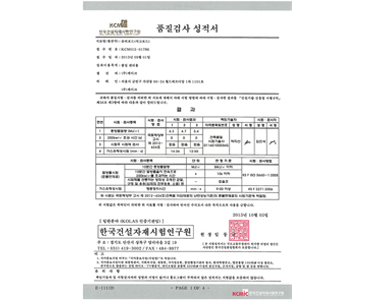

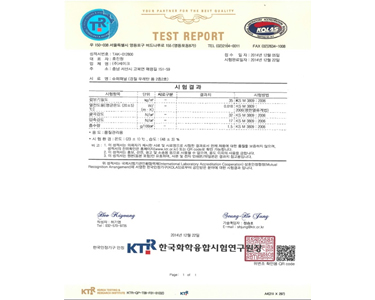

Land and Ocean department of central government assured the certificate of “Fire Retardant Test”

Land and Ocean department of central government assured the certificate of “Fire Retardant Test”

2. Lowest thermal conductivity and high performance of insulation

Because the Super Panel that has PIR(Poly – isocyanurate) body is the thinnest and most effecvtive thermal insulation, there are many available solutions making them suitable for both new building applications and refurbishment projects where optimisation of space is important.

| Density | Kg/㎡ | 35 |

|---|---|---|

| Conductivity | W/(m•k) | 0.019 |

| Flexural Strength | N/c㎡ | 32 |

| Compression Strength | N/c㎡ | 17 |

| Water Absorption | g/100c㎡ | 1.5 |

3. Eco- friendly construct materials

super panel is strong against water absorption, humidity.

Because Super panel could prevent the in and outside condensation of wall, it doesn’t need water proof processing in construction to reduce the bacteria.

| Items | Unit | Discharge/degree |

|---|---|---|

| TVOC | (mg/m2h) | trace |

| 5VOCs | (mg/m2h) | 0.000 |

| HCHO | (mg/m2h) | trace |

| CH3CHO | (mg/m2h) | 0.000 |

4. Excellent technology and economic price

The reason of superior quality, optimal facility and reasonable price.

a. The verified chemical recipe of Sake-made PIR system house

b. Optimal and continuous laminating machine

5. The shortening of construction period

Work together both finishing material of exterior and the insulation board inside of the wall coincidently.

It could mitigate the cost of materials and labor’s payment.

the comparison of formal and new operating type in workplace.

| Former type | New method of construction | |

|---|---|---|

| Process management | 1st. insulatione 2nd finishing wall | One Touch type , work together |

| Required time for works | Double times | Time shortening |

| Cost / Expenditure | Up ↑ | Reducing ↓ |

| Effect | 1. simple procedure |

Data Sheet

| Size | W: 600mm, L: 2000~3000mm |

| Thickness | 50mm~200mm |

| Surface | Gypsum , CRC, MG board, artificial stones |

| Density | 35kg/m3 ~ (just pir board) |

| Thermal conductivity | 0.019~0.021W/mk |

Real application in housing field

| Application | Comparision | |

|---|---|---|

| Apartment/Public building Town house/Factory |

Exterior finishing (art stones, CRC board ) Interior wall (gypsum , MGO board) |

– New house construction – Excellent insulation – Surface finishing – Perfect fire retardant |

| Prefabricated house – urban residence – rural house – field dwelling house |

Wall + roof+ interior+ exterior+ finishing + remodeling = One touch construction |

– Passive house – General residence – Standard cubic style – Order made type |

LANGUAGE

LANGUAGE