Continuous Laminating Machine is

Sake panel line has accumulated experience to make Super panel, Bio Clean duct and Super board since1997.

And as a manufacturer of panel, we know the week point and difficult situations in making panel.

Especially we have adjusted our pouring spray machine design to a various environment working conditions.

As it is very hard to maintain the operating skills to cover the capricious changes of climates.

Product’s Benefits

Speciality

This laminating conveyor system is appropriate for the clean duct panel, insulating super board and super board.

The special and efficient technology of this facility is originated from many empirical experiences for 20 years.

We are concentrated on the benefits and interests of manufacturers.

So, it would be the best combination both chemical recipe and operating line system

Optimal design

– Assembling just, essential, appropriate parts and element inro a set.

– Efficient and effective design : we know what is difficult and excrescenct part in operating.

– This line system is very reasonable and competitive price.

Before service and After service

– As our design concept is focusing on simplicity and sustainability, it is very easy to maintain and repair

– We are prepared to discipline the new operators how to deal with the system and producing know how.

– We always maintain the spare parts to repair and mend, so it can save your time and effort to find out the spares.

Verified recipe of polyol system

20년간 축적된 노하우와 국내외 협력사들과의 긴밀한 협조로 원액과 기계의 효율적인 조합을 통해 안정된 원액과 제품의 품질을 보장합니다

– The combination of chemical recipe, operating skills and line machine is not easy for new comer, so we could provide those things at a time .

– The changeable situations are difficult to control to maintain the same quality. To spare loss, we could open our technologies to our platform company.

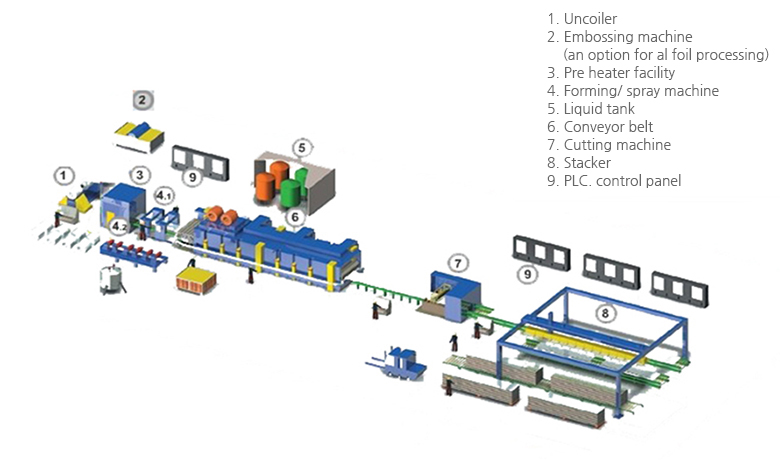

The lay out of machine

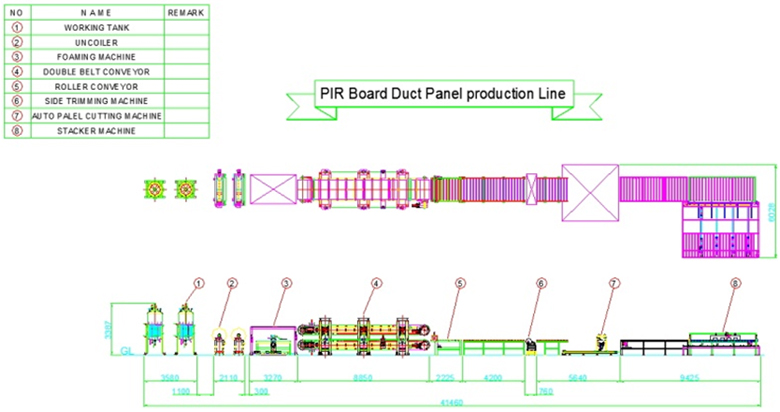

Blueprint of machine line

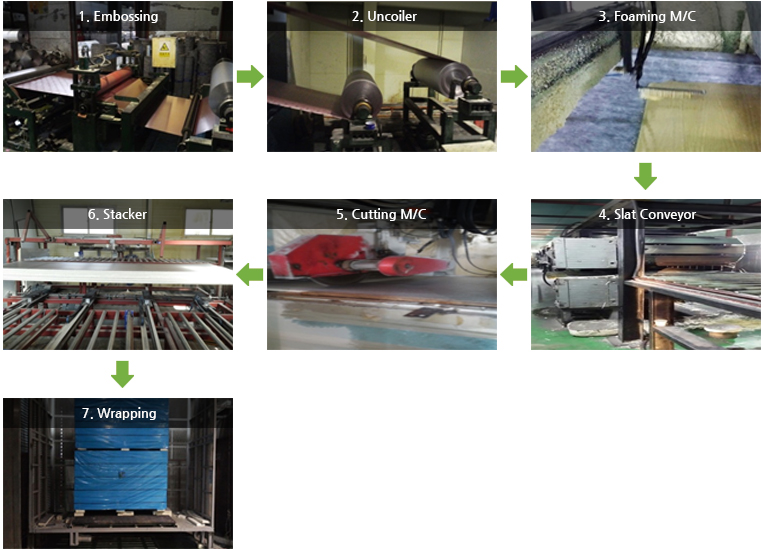

Production Process

Additional facilities by the optional order

Cooling conveyor system

Cooling conveyor system is necessary to produce no surface panel.

Anti- explosive facility is essential to use C-Pentane blowing agency.

Anti-explosive facility

– Anti- explosive facility is essential to use C-Pentane blowing agent.

| HCFC-141b | C-pentane | |

| ODP | 0.11 | 0 |

| GWP | 713 | <25 |

| Price(USD) | 2-2.5/kg | 1-1.4/kg |

LANGUAGE

LANGUAGE